ProTecta Synthetic Engine Oil Booster

ProTecta Synthetic Engine Oil Booster: ASTM-D-6335-98

ASTM-D-6335-98 STANDARD TEST METHOD FOR DETERMINATION OF HIGH TEMPERATURE DEPOSITS BY THERMO-OXIDATION ENGINE OIL SIMULATION TEST

Scope

This test method covers the procedure to determine the amount of deposits formed by automotive engine oils utilizing the thermo-oxidation engine oil simulation test (TEOST). An inter-laboratory study has determined it to be applicable over the range from 10 to 65 mg total deposits.

Summary of Method

A sample of the engine oil at a temperature of 100°C that contains ferric napthenate and is in contact with nitrous oxide and moist air is pumped at a set flow rate past a tared depositor rod. The rod is resistively heated through twelve, 9.5 minute temperature cycles that go from 200 to 480°C. When the twelve cycle program is complete, the depositor rod rinsed of oil residue and dried and the gross rod mass obtained. The sample is flushed from the system and filtered through a tared filter. The mass of deposits on the rod plus the mass of deposits on the filter is the total deposit mass.

Significance

The test method is designed to predict the high temperature deposit forming tendencies of an engine oil. This test method can be used to screen oil samples or as a quality assurance tool.

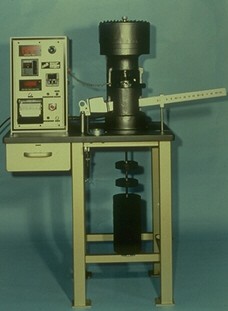

As a consequence of a close collaboration between Chrysler Corporation and Savant Laboratory, a small bench-top instrument was developed to simulate engine operating stresses on the engine oil. The area of particular interest was deposit formation. The ability to change a variety of test parameters on the TEOST apparatus lends itself to research work beyond the original Protocol 33C procedure.

Since its introduction, the TEOST Protocol 33C has been incorporated in the ILSAC GF-2 specification. This test, along with a new protocol yet to be named, is expected to also be included into the GF-3 requirement.

Products Tested

ProTecta Engine Treatment was tested with a motor oil.

Independent Testing Laboratory:

Date Completed: 2/14/2001 Test considered Valid-PASS

Lubrizol Laboratories in Wickliffe, Ohio. Lubrizol is a leading additive supplier for the oil companies in the U.S. The test was run twice.

Date Completed 9/19/02 Test Considered Valid-PASS

Date Completed 9/25/02 Test Considered Valid-PASS

What is the significance of this test?

ProTecta Engine Treatment aids motor oil in its lubrication function as some oil must reach the area of the top piston ring in order to lubricate the rings and the cylinder walls. This oil is then exposed to the heat and flame of burning fuel, and part of it actually burns off. ProTecta's synthetic base burns cleanly under these conditions, leaving almost no carbon residue. The detergent/dispersant additives in ProTecta work with motor oil to keep the piston rings free in their grooves, thereby maintaining compression and minimizing the amount of oil reaching the combustion chamber. This not only reduces oil consumption but more importantly, keeps combustion chamber deposits at a minimal amount. ProTecta unlike other engine treatments, not only treats the metal but is fully fortified with additives to treat the oil as well. Almost every new engine oil category improvement calls for additional additives to work under engine manufacturers guidelines. This is especially true in engines equipped with turbochargers as they require a steady flow of oil to the center of the turbo bearings to provide necessary lubrication and cooling.

According to the API "Since stop-and-go driving most often does not permit the engine to reach efficient temperatures, it is actually among the most severe types of car operation. Under these conditions the rate of oil contamination is high, and the ability of the oil to overcome the effects of the contamination is low. Low-temperature driving, short runs, and light-load operation all promote water accumulation, fuel dilution, and the formation of sludge, varnish, and corrosive acids". This is why ProTecta us formulated with additives to prevent this accumulation of deposits.

Why do I Need This Extra Protection?

The types of service we drive under and the climatic conditions that we operate our engines under vary greatly. When traveling at moderate speeds on short trips or driving in traffic under stop and go conditions, we use only a fraction of the engines power. Because the cooling systems must cool under a variety of conditions, they can overcool the engine during those short trips we take. In such light duty service engines and motor oils warm up slowly and do not often reach proper operating temperatures. Under these conditions incomplete combustion will occur, as soot and partially oxidized hydrocarbons undergo further oxidation in the crankcase, which forms sludge and varnish deposits. ProTecta with its detergent and dispersants offer extra protection in such driving conditions.

ProTecta Synthetic Engine Oil Booster: ASTM-D-2783

ASTM-D-2783 Standard Method for MEASUREMENT OF EXTREME-PRESSURE PROPERTIES OF LUBRICATING FLUIDS (FOUR-BALL METHOD)

- Scope

- Summary of Method:

- Significance:

This method covers the determination of the load-carrying properties of lubricating fluids. The following two determinations are made:

i. Load-wear index and

ii. Weld point by means of the four-ball extreme-pressure (EP) tester

The tester is operated with one steel ball under load rotating against three steel balls held stationary in the form of a cradle. Test lubricant covers the lower three balls. The rotating speed is 1760 ± 40 rpm. The machine and test lubricant are brought to 18.33 to 35.0°C (65 to 95°F) and then a series of tests of 10-second duration are made at increasing loads until welding occurs. Ten tests are made below the welding point. If ten loads have not been run when welding occurs and the scars at loads below seizure are within 5% of the compensation line then no further runs are necessary. The total can be brought to ten by assuming that loads below the last non-seizure load will produce wear scars equal to the "compensation scar diameter".

This method, used for specification purposes, differentiates between lubricating fluids having low, medium, and high level of extreme pressure properties. The user of this method should determine to his own satisfaction whether results of this test procedure correlate with field performance or other bench test machines.

Products Tested:

| Name of Product | Load Wear Index | Seizure-Weld Load |

| Protecta Engine Treatment® | 187.7 | No Seizure |

| Motorkote™ | 158.07 | (seized) 620 Kilograms |

| Prolong® | 152.8 | (seized) 800 Kilograms |

| Energy Release® | 111.7 | (seized) 620 Kilograms |

| Slick 50® | 37.04 | (seized) 250 Kilograms |

| Duralube® | 32.73 | (seized) 200 Kilograms |

| Mobil 1® Tri-Synthetic motor oil | 28.96 | (seized) 200 Kilograms |

| Lucas® oil stabilizer | 21.42 | (seized) 126 Kilograms |

| Z-Max® | 14.70 | (seized) 126 Kilograms |

All products, except Motorkote™, were tested without dilution at 100% concentration by Petro-Lubricant Test Labs, Inc. in New Jersey. Motorkote™ values were taken from their website thus we are unable to vouch for accuracy. It should be noted that we make no claims of any products tested except to provide the values through conducting the American Society of Testing Materials standardized test D-2783 as performed by the independent laboratory.

So Are Additives that Reduce Extreme Pressure Really Necessary?

According to the American Petroleum Institute (API) or the major oil companies spokesman, which is published in their Motor Oil Guide, they claim the following: "Extreme pressure conditions can develop between heavily loaded parts from lack of lubrication, inadequate clearance, extreme heat, and sometimes as a result of using the wrong type or grade of lubricant for the operating conditions of the engine. In modern engines the valve train with its cams, valve lifters, push rods, valve stem tips, and parts of the rocker arms operate under extreme pressure because they carry heavy loads on very small contact areas. Unit loading, which may be as high as 200,000 pounds per square inch, is many times greater than the loads on the connecting rod bearings or on the piston pins." Because of higher unit loading, higher engine speeds, and the smaller size of certain parts, modern engines have many components that operate under boundary or extreme pressure conditions much of the time".

Do Motor Oils Contain Extreme Pressure Additives?

Research has shown that NO motor oils contain extreme pressure additives presently. This includes major motor oil company's petroleum and synthetic products as well as specialty synthetic motor oil producers such as Amsoil® , Redline®, and Royal Purple®.

What About Wear At Start Up?

This is a question that gets asked a lot and many of the additive companies mention this in their marketing. The reason for this is that under some conditions it is not possible to maintain a lubricating film between moving parts, and thus intermittent metal-to-metal contact occurs. Generally this happens between high spots on sliding surfaces. Under such conditions the load is only partially supported by the motor oil film. What happens is the film is ruptured, which causes the metal-to-metal contact. When this occurs, heat is caused by the metal surfaces rubbing against each other.

According to the API "unless counteracted by proper additive treatment, the result is either immediate seizure or the tearing apart and roughening of the surfaces. Boundary lubrication conditions always exist during engine starting and often during the operation of a new or rebuilt engine. Boundary lubrication is also found around the top piston ring where oil supply is limited, temperatures are high, and a reversal of piston motion occurs." This is why ProTecta relies on "inter-metallic" extreme pressure additives to reduce wear and protect where heat can shear the motor oil.

ProTecta Synthetic Engine Oil Booster: ASTM-D-6557-00

ASTM-D-6557-00 STANDARD TEST METHOD FOR EVALUATION OF RUST

PREVENTIVE CHARACTERISTICS OF AUTOMOTIVE ENGINE OILS

- Scope

- Summary of Method:

- Significance:

- API SL

- ILSAC GF-3

This test method covers a Ball Rust Test (BRT) procedure for evaluating the antirust ability of fluid lubricants. The procedure is particularly suitable for the evaluation of automotive engine oils under low-temperature, acidic service conditions.

Multiple test tubes, each containing test oil and a specimen, are placed in a test tube rack, which is attached to a mechanical shaker. The shaker speed and temperature are controlled. Air and an acidic solution are continuously fed into each test tube over an 18 hour period to create a corrosive environment. The specimens are then removed, rinsed, and analyzed by an optical imaging system designed to quantify the antirust capability of each test oil.

This bench test method was designed as a replacement for Test Method D-5844. Test Method D-5844 was designed to measure the ability of an engine oil to protect valve train components against rusting or corrosion under low temperature short-trip service, and was correlated with vehicles in that type of service prior to 1978. Correlation between these two test methods has been demonstrated for most, but not all, of the test oils evaluated.

Sequence IID test (ASTM D 5844), which evaluates a lubricant's ability to prevent engine corrosion.

The IID test has been correlated with vehicles used in short-trip service prior to 1978, particularly regarding rusting. The ball rust test, ASTM D 6557, is an 18-hour bench test designed to simulate the Ball Rust Test Equipment and Procedure.

The ball rust test uses procedures for engine oil categories:

The ball rust test fixture is a custom-built bench rig based on a temperature-controlled shaker table. A syringe pump is used to inject acid into the test oil, while a compressed air manifold system supplies clean, dry air into the oil at a controlled rate of 40 mL/min. Tests are run for 18 hours with the test oil environment controlled at 48°C. A solution of acetic, HBr, and HCl acids and deionized water is injected into the oil at a rate of 0.193 mL/hr.

Ball Rust Test Results

At test end, the hydraulic lifter balls are removed from the rig, washed according to procedure, and rated for surface discoloration using an optical rating/computer/video system.

Each candidate oil is typically run in pairs during a single test. Up to five oils can be run simultaneously, with one or more of the oils as a reference oil. An average gray scale value of 100 minimum is required for ILSAC GF-3 engine oil category.

Products Tested:

ProTecta® Engine Treatment was tested with a motor oil.

Independent Testing Laboratory:

Date Completed: 1/16/2001 Test considered Valid-PASS; Fresh Ball Gray Value SOT:

134, EOT: 134. Average Gray Value for ProTecta® Engine Treatment: 119.

Why Is This Test Important?

Again, according to the API , which is a leading source in motor oil performance, corrosion can become a problem. "In addition to water and the byproducts from incomplete combustion of the fuel other corrosive combustion gases also get past the rings and are condensed or dissolved in the crankcase oil. The life of engine parts depends in part on the ability of the motor oil to neutralize the effects of these corrosive substances. This is why ProTecta® utilizes a synthetic base oil and is fortified with special oxidation and corrosion inhibitors.